The Relevance of a Dependable Pipes and Heating System

Making Use Of Pipeline Connectors Effectively

When it concerns efficiently using pipe connectors, recognizing the subtleties of option and installment can make a significant difference in the end result of your project. You might believe you have actually every little thing covered, yet there's one crucial aspect that typically gets forgotten, potentially resulting in expensive errors. By paying attention to this often underestimated aspect, you can assure a smooth operation and stay clear of unexpected problems down the line.

Key Takeaways

- Pick compatible products for safe and secure links.

- Correct sizing prevents leaks and architectural issues.

- Think about materials and stress demands.

- Tidy pipe finishes prior to installation for integrity.

- Usage two wrenches for tight, leak-free connections.

Sorts Of Pipe Connectors

When picking pipeline connectors for your project, it is important to comprehend the different kinds readily available to assure correct compatibility and capability. Port materials play a considerable function in the performance of your piping system. Usual products include PVC, copper, brass, and stainless steel, each offering unique advantages and constraints. Take into consideration the specific demands of your task to determine the most appropriate material for your ports.

Joint kinds are an additional important element to ponder when choosing pipeline ports. Typical joint kinds include compression, push-fit, soldered, and threaded connections. The joint kind you pick will rely on elements such as the materials being connected, the necessary strength of the joint, and convenience of installment and upkeep.

Adapter sizing and compatibility are vital to make certain a leak-free and reliable piping system. Make certain to precisely determine the pipeline diameter and pick adapters that match these measurements exactly. Making use of incompatible adapters can bring about leakages, pressure declines, and general system ineffectiveness. Consequently, constantly double-check the sizing and compatibility of adapters before installment to prevent any prospective issues down the line.

Choosing the Right Adapter

To pick the correct adapter for your project, think about the certain needs and materials involved. Adapter compatibility is essential to guarantee a secure and leak-free connection. Prior to selecting, confirm that the connector is compatible with the kinds of pipelines you are signing up with. Various materials such as PVC, copper, or steel may call for specific adapter kinds to protect an appropriate fit.

Proper sizing is one more essential variable to remember. Using a connector that is as well small or also large for the pipes being attached can bring about leakages or perhaps architectural issues. Action the diameter of the pipelines precisely to choose a port that fits well without any spaces.

When picking an adapter, additionally take into consideration the intended usage and the stress that will certainly be exerted on the joint. Choosing a port that satisfies the pressure requirements of your task is vital to prevent any mishaps. By paying attention to adapter compatibility and proper sizing, you can make sure a successful and resilient pipeline link.

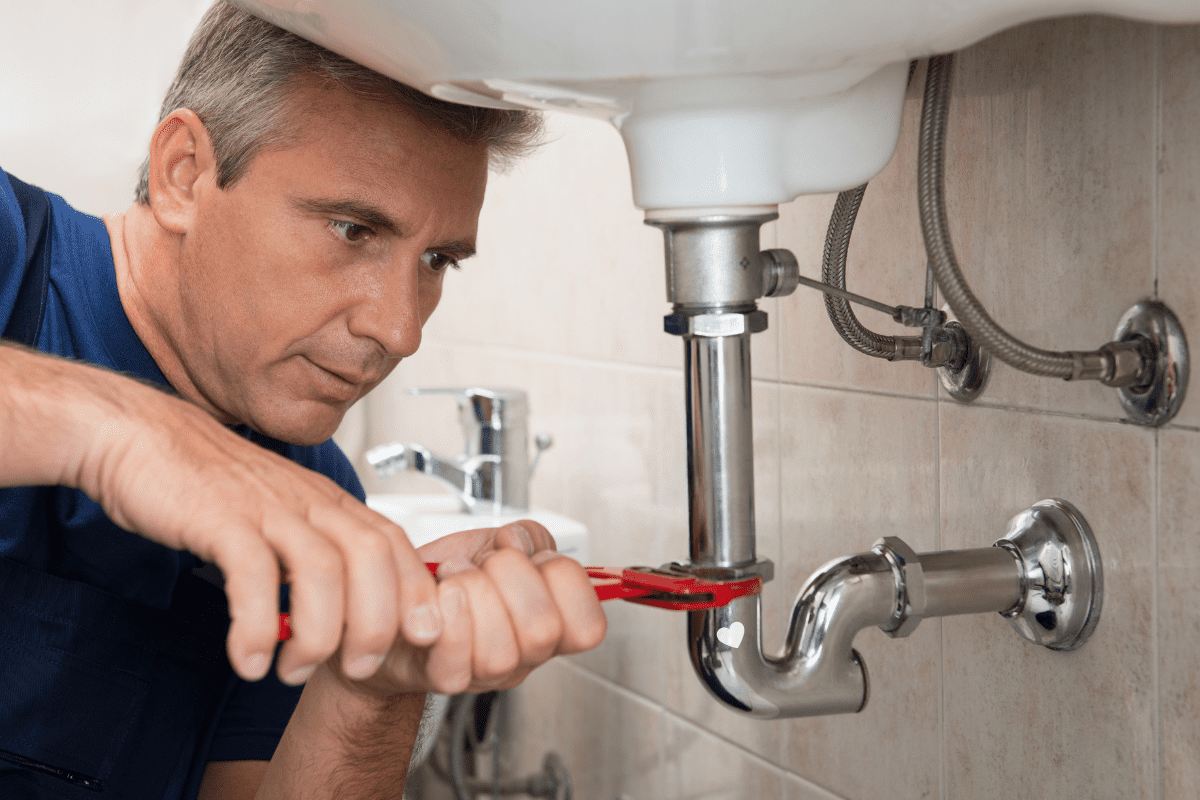

Mounting Pipeline Connectors

Consider the adhering to actions to ensure a successful setup of pipeline connectors. Correct installation is essential to ensure the effectiveness and long life of your pipes system. To begin with, always clean the pipeline ends completely to remove any dust, particles, or old sealer. Next off, use an also layer of plumbing's tape or pipe joint compound to the male strings before connecting the pipelines. When tightening up the ports, utilize two wrenches to prevent twisting and make sure a protected fit.

Troubleshooting throughout installation is important. Usual errors include over-tightening, which can result in leakages, or under-tightening, causing loose connections. If you encounter leakages after setup, attempt re-tightening the adapters or reapplying sealer. Furthermore, regularly examining your pipeline connectors for deterioration is vital for maintenance. Keep an eye out for signs of corrosion, corrosion, or noticeable damages, and replace any damaged ports promptly to avoid leakages and water damages.

Guaranteeing Leak-Free Connections

Guarantee leak-resistant links by complying with appropriate installation techniques when utilizing pipeline adapters. blocked toilet plumber To safeguard a dependable seal and stop leakages, it is crucial to focus on stopping rust and using proper sealing strategies. Rust can deteriorate the port gradually, bring about prospective leaks. To combat this, think about utilizing connectors made from corrosion-resistant materials like stainless steel or brass. Additionally, applying a corrosion-resistant finish can even more protect the adapters from deterioration.

When it concerns securing strategies, ensure to clean the pipeline ends extensively before connecting them. Any type of particles or dust left on the pipes can endanger the seal and bring about leakages. Use appropriate securing materials such as Teflon tape or pipeline joint compound to produce a tight seal. Apply the sealing material evenly and regularly around the strings to prevent any type of voids where leakages might take place. By paying attention to protecting against rust and using appropriate sealing techniques, you can properly guarantee leak-resistant links with your pipe ports.

Preserving Pipe Connectors

Regularly check out and tidy pipeline adapters to keep peak performance and durability. Preventing rust is important in preserving the stability of your pipeline adapters. Deterioration can deteriorate the ports, resulting in leaks and possible failings. By performing routine assessments, you can identify any indications of deterioration early and take necessary preventive measures.

During your evaluations, pay very close attention to any corrosion, discoloration, or pitting on the adapters. If you observe any of these indicators, think about applying a rust prevention or safety finishing to prevent further corrosion. Furthermore, cleaning up the adapters with a gentle option and removing any kind of debris or accumulation can help expand their life-span.

Aside from stopping rust, routine examinations likewise enable you to check for any kind of loosened fittings or damaged elements. Tightening up loosened links and changing any kind of worn-out parts without delay can help keep the effectiveness of your pipeline system.

Regularly Asked Questions

Can Pipeline Connectors Be Re-Used After Removal?

Yes, you can recycle pipe adapters after removal. This practice promotes environmental sustainability by decreasing waste. Think about recycling choices to even more reduce influence and save money. Appropriately preserved ports can be safely gotten rid of and recycled multiple times, using cost savings and reducing the requirement for new products. Bear in mind to inspect connectors for wear and tear prior to recycling to guarantee peak efficiency and safety.

Exactly How Do Pipeline Connectors Affect Water Pressure?

When it concerns water pressure, pipeline connectors play a crucial role. Appropriate link toughness warranties minimal stress loss and reliable water circulation. Material compatibility is vital to preserving stress levels. An inequality can result in leakages or lowered water circulation. Understanding just how pipeline connectors impact water pressure is necessary for a well-functioning pipes system.

Are Pipe Connectors Suitable With All Pipe Materials?

Pipe connectors are usually suitable with different pipeline materials, yet it's important to ensure correct setup methods. Various types of ports might work much better with details pipe materials, so it is necessary to pick the right one for the work. Correct installation methods, such as making use of the correct sealers and making sure a protected fit, can aid avoid leakages and assure peak performance. Constantly comply with producer guidelines to guarantee compatibility and performance.

Can Pipeline Connectors Be Repainted or Coated?

Yes, you can paint pipeline ports to match your wanted visual. Painting choices allow you to tailor the appearance of your adapters to blend flawlessly with your overall design. Furthermore, some pipeline ports can be covered for included defense against rust or other ecological variables. Covering options offer an extra layer of protection, ensuring the longevity and sturdiness of your adapters in numerous conditions.

Do Pipe Connectors Call For Normal Evaluations for Safety And Security?

For precaution, do routine evaluations on pipe adapters. Examine them commonly for prospective threats. Maintenance checks should be done often to ensure everything is secure.